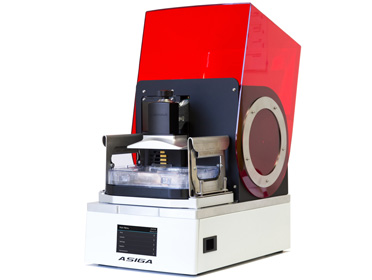

Asiga MAX UV – Advanced Desktop Dental 3D Printer

The Asiga MAX UV is the world’s most advanced lab 3D printer offering exceptional productivity in a small footprint. Manufactured and serviced in Australia.

Build Volume: 119 x 67 x 75mm

Print Resolution: 62 μm (x, y Axis)

Inclusions:

- Asiga Max UV

- Asiga Calibration Tool Kit

- Asiga Flash

- Asiga Build Tray

- 1kg Dental Resin

- Asiga Composer Software

Description

| Product specification | |

| Build Volume X, Y, Z | 119 × 67 × 75mm 4.69 × 2.64 × 2.95 inches |

| Pixel Resolution | 62µm |

| Technology | DLP |

| LED Wavelength | 385nm (high power UV LED) or 405nm |

| Material Compatibility | Asiga materials, 100% Open Material System — use any suitable third party material |

| Software | Asiga Composer software. Lifetime updates included |

| File Inputs | STL, SLC, PLY, STM (Asiga Stomp file format) |

| Network Compatibility | Wifi, Wireless Direct, Ethernet |

| Power Requirements | 100 to 240 VAC, 50/60 Hz, ≤2 Amps |

| System Sizing | 260 × 385 × 370mm / 19.3 kg 10.2 × 15.2 × 14.5 inches / 42.6 lb |

| Packed Sizing | 410 × 500 × 480mm / 21.6 kg 16.1 × 19.7 × 18.9 inches / 47.6 lb |

| Warranty | 12 months manufacturer’s warranty |

| Technical Support | Unlimited lifetime technical support included |

| Bundle Includes | 3D printer, Composer software, 1 kg Asiga material, 1L build tray, Asiga Flash post-curing chamber, calibration toolkit |

62µm Print Precision

Optimized for both dental and audio lab or clinic environments.

Digital Dentistry

Manufacture dental orthodontics, crown & bridge, surgical guides, dental models, custom trays and partial dentures.

After extensive internal testing of a variety of 3D printing systems, the Asiga MAX UV is clearly one of the best desktop 3D printers in terms of print quality and consistency for the tested dental indications.

SPS™ Smart-Positioning-System Technology

Asiga’s unique SPS™ process guarantees every layer is formed accurately. Accurate layer formation is the key to achieving consistently accurate results in any production environment.

Open Material System

Select from a range of Asiga materials with the added benefit of using any material from any manufacturer. Over 380 materials available.

Why 385nm UV LEDs?

3D printing materials cure faster at deeper UV wavelengths (385nm) reducing XY scattering and over-cure. The result is consistent accuracy, production reliability and the ability to process water-clear materials.

GN ReSound is a global leader in intelligent audio solutions and we print with confidence on the Asiga MAX UV.

Fastest Material Changeover

The fastest material change over than any other product on the market. Complete in under 30 seconds.

Single Point Calibration

Simple platform calibration and internal radiometer for automatic LED calibration.

Trusted by Laboratories Globally

Build to perform in the most challenging production environments.

Free and Unlimited Lifetime Technical Support

Guaranteed.

Affordable Digital Manufacturing

It’s something Asiga invented.